what we can do to help you ?

High-precision quick-change fixture application design

Part holding solutions also include systematic, automated and modular design.

Understand the processing requirements and equipment status, optimize and deepen the design scheme according to the strict requirements, and produce high-standard fixture in strict accordance with the requirements. In addition, there are later to provide technical support.

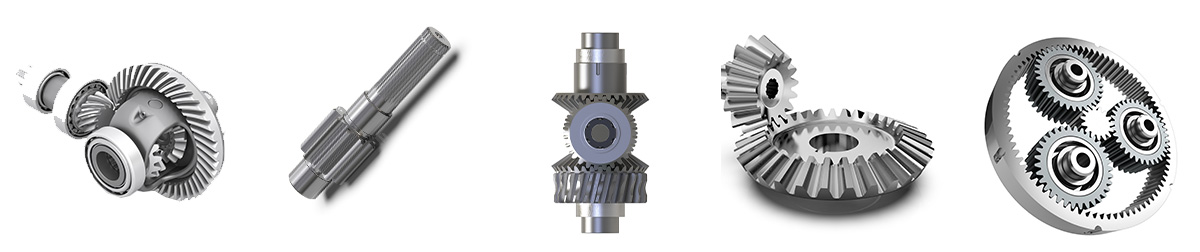

1.Gear processing parts processing clamping solutions

Gear machining is a complex process, including a complete technological flow; Gear processing parts processing clamping solutions

Gear machining is a complex process, including a complete technological flow; The proper clamping system for this process can effectively improve production efficiency; Envision is able to design, produce and manufacture fixture for all processes of gear processing. Whether it is gearbox, drive system or other gears, Envision fixture can provide high precision and high quality fixture in strict accordance with customer requirements.

* the CAM set

* shaft gear

* bevel gear

* timing wheel

* within the set of teeth

* spline shaft

* gear

* helical gear

* Planetary gear

* the drive shaft

* straight gear

* Turbine disc teeth

* big gear

2. Intelligent assembly parts processing clamping solutions

With the advent of the era of industry 4.0, systematization, digitalization, intellectualization and digitalization have become the overall direction of China's manufacturing industry reform. Intelligent manufacturing system can achieve the innovation and reform of production mode, The core patent of Envision adhesive sleeve, can achieve a larger range of clamping, simple replacement, can be matched with manipulator easily realize automation, intelligent production.

3. Agricultural machinery parts processing clamping solutions

Agricultural machinery is very important for the construction of modern agriculture, is power machinery, all terrain machinery, small machine and high-end facilities horticulture unmanned intelligent machinery development, manufacturing process, some important part imports jig, east dragon has 15 years experience in import jig localization, east dragon fixture can meet the demand of agricultural machinery industry in different parts of clamping, Effectively improve the quality stability of machined parts.

Power system: CAM bushing; Jacket; The piston mouth; The camshaft

Transmission system: star sleeve/ball bearing; Ball bearing cage; Drive axle housing; Bevel gear/ball hinged head; Constant velocity universal joint

Rotary mechanism: brake (brake disc); Hydraulic motor; Planetary gear reducer; Rotary gear ring/lubricating oil cup; Central rotary joint

4. Machine tool equipment parts processing clamping solutions

Machine tool is the "working machine" in the field of machinery, especially high-end machine tools to fixture precision and quality requirements are extremely high, Envision has nearly ten years of imported fixture localization experience, and many foreign machine tool factories deep cooperation, to provide supporting services. In particular, all the machine tools and fixtures related to gear processing can be designed and manufactured in strict accordance with requirements and provide technical support.

* Gear hobbing machine *Gear grinding machine *Gear honing machine *Gear shaper *Shaving machine

* lathe *CNC *Machine parts

5.Construction machinery parts processing clamping solutions

Construction machinery is an important part of the national equipment industry. It is developing towards intellectualization, electrification, cleanliness and high-tech, and also puts forward higher requirements on the quality, precision, noise suppression and manufacturing energy consumption of parts and components. Envision's clamping solutions meet the quality requirements and requirements of the construction machinery industry; Whether it is gearshift, transmission, drive, brake or other parts of construction machinery, Envision can design and manufacture clamping systems to ensure efficient, stable and reliable processing.

Power system: CAM bushing; Jacket; The piston mouth; The camshaft

Transmission system: star sleeve/ball bearing; Ball bearing cage; Drive axle housing; Bevel gear/ball hinged head; Constant velocity universal joint

Rotary mechanism: brake (brake disc); Hydraulic motor; Planetary gear reducer; Rotary gear ring/lubricating oil cup; Central rotary joint

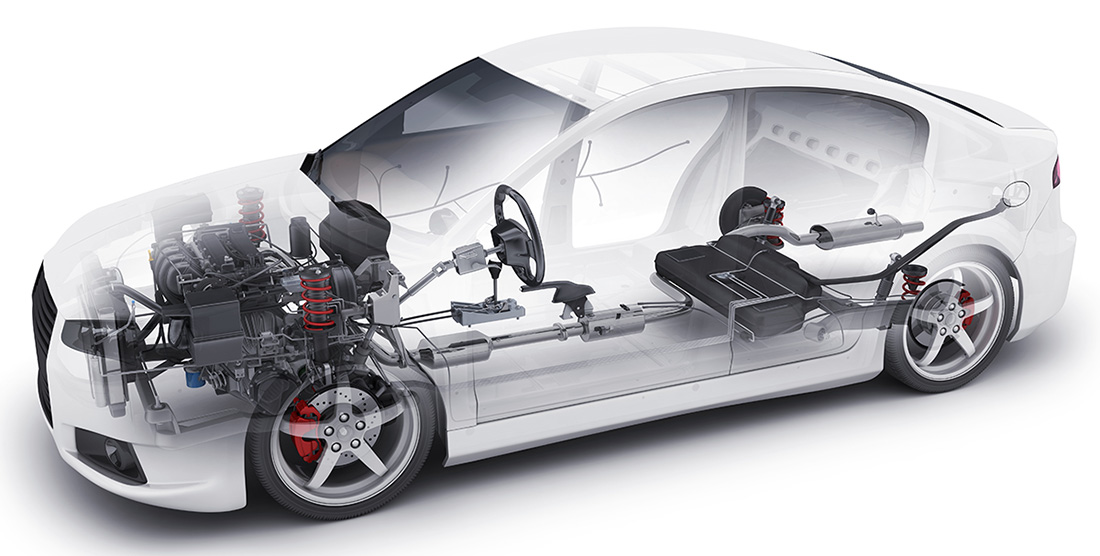

6.Automotive industry parts processing clamping solutions

The automobile industry has strict requirements for products and high precision requirements for complex parts, while the rise of new energy vehicles puts forward higher requirements for new material processing, thin-wall parts processing and special parts processing. Envisionfocus on parts fixture design, development and manufacturing, to meet the clamping needs of different workpiece, to solve the problem of parts processing clamping, to create a more efficient and intelligent production mode.

Engine: CAM shaft bushing; Jacket; The piston; Nozzle; The camshaft

Turbocharger: compressor impeller; The supercharger. Turbine impeller

Transmission: switch CAM; Gear; The sun's axis; Differential housing

Brake system: brake disc

Transmission system: star sleeve/ball bearing; Ball bearing cage; Constant velocity universal joint; Drive axle housing; Bevel gear/ball hinged head

Accessories: tow hook

7. Aerospace industry parts processing clamping solutions

The environment in which aerospace equipment is located is extremely complex and changeable

The material and technical requirements of the parts are very strict, and the parts must ensure ultra-high precision and strict performance requirements

Hydraulic valve housing support

(Frame and wing)

turboshaft

The turbine bearing

Turbine blade (power unit/turbine)

The valve block

Seat slide bracket (internal equipment)

Turbine housing parts

The turbine wheel

Brake cover system

Hydraulic pump housing (landing flap control)

Landing gear cylinder

Compressor impeller

Worm gears

Main landing gear (aircraft landing gear)

We do our best to make the gear turn more accurately!